Change Language :

iglide® N54 - Material data

Materials table

| General features | Unit | iglide® N54 | test method |

|---|---|---|---|

| Density | g/cm3 | 1.13 | |

| Color | green | ||

| Max. moisture absorption at 73°F/50% R. H. | Wt.-% | 1.6 | DIN 53495 |

| Max. moisture absorption | Wt.-% | 3.6 | |

| Coefficient of surface friction, dynamic, against steel | μ | 0.15–0.23 | |

| P x v value, max. (dry) | psi x fpm | 14,000 | |

| Mechanical properties | |||

| Modulus of elasticity | psi | 261,000 | DIN 53457 |

| Tensile strength at 68° F | psi | 10,150 | DIN 53452 |

| Compressive strength | psi | 4,351 | |

| Maximum recommended surface pressure (68° F) | psi | 8,700 | |

| Shore D hardness | 74 | DIN 53505 | |

| Physical and thermal properties | |||

| Upper long-term application temperature | °F | 176 | |

| Upper short-term application temperature | °F | 248 | |

| Lower application temperature | °F | -40 | |

| Thermal conductivity | W/m x K | 0.24 | ASTM C 177 |

| Coefficient of thermal expansion (at 73° F) | K-1 x 10-5 | 9 | DIN 53752 |

| Electrical properties | |||

| Specific volume resistance | Ωcm | < 1013 | DIN IEC 93 |

| Surface resistance | Ω | < 1011 | DIN 53482 |

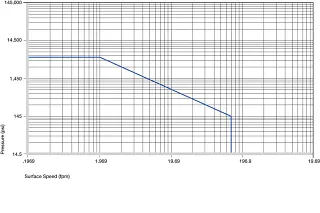

Permissible p x v values for iglide® N54 plastic bushings running dry against a steel shaft, at 68°F

Permitted p x v values

For iglide® N54 plastic bushing with 0.03 inches (1 mm) wall thickness under dry running conditions against a steel shaft, at 68°F, installed into a steel housing.

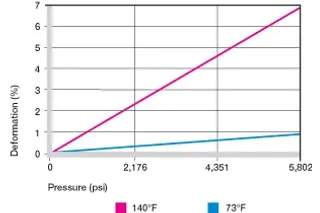

Deformation under load and temperature

Compressive Strength

iglide® N54 is the first iglide® material based largely in biopolymers. In addition to the already assured lubricant-free properties of iglide® materials, this is one further contribution to positive environmental stewardship. The good coefficients of friction in conjunction with holding times ensure that these materials have a permanent place in the iglide® product range.

Permitted surface speeds

Even if the typical applications for iglide® N54 plastic bushings are more commonly for intermittent service, depending on the type of motion, the maximum attainable speeds can be quite high. The speeds stated in table are limit values for the lowest bearing loads. As loads increase, the admissible speed is reduced with higher loads due to the limitations of the pv value.

| fpm | Rotary | Oscillating | Linear |

|---|---|---|---|

| Constant | 157 | 118 | 197 |

| Short-term | 295 | 216 | 393 |

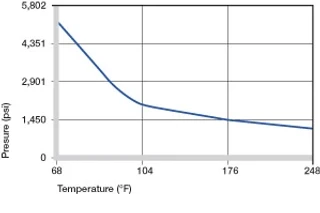

Temperatures

The short-term admissible temperature limit is +248 °F, thus permitting the use of iglide® N54 plastic bushings in all applications with elevated ambient temperatures. However, the compressive strength of iglide® N54 plastic bushings decreases as temperatures increase. The additional frictional heat in the bushing system should be taken into account when considering the temperature limits.

| iglide® N54 | Application temperature |

|---|---|

| Lower | - 40 °F |

| Upper, long-term | + 176 °F |

| Upper, short-term | + 248 °F |

| Additional axial securing | + 122 °F |

| Temperature limits for iglide® N54 |

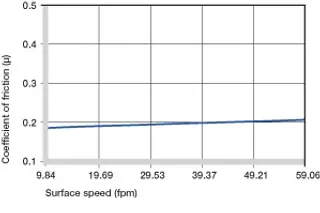

Coefficients of friction of iglide® N54 as a function of the running speed; p = 145 psi

Friction and wear

iglide® N54 has a low coefficient of friction. However it must be noted that a gliding partner with a rough surface finish increases the friction. We recommend shaft surface finishes 4 to 16 rms.

The coefficient of friction of iglide® N54 plastic bushings is only marginally dependent on the surface speed.

The influence of the load is greater; an increase in load lowers the coefficient of friction up to 0.08.

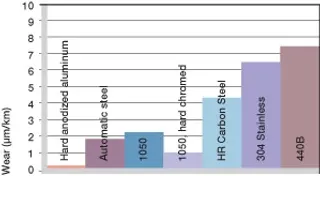

Wear of iglide® N54, rotating applications with different shaft materials, p = 145 psi, v = 59 fpm

Shaft materials

It is important to select a suitable shaft material. As a rule, iglide® N54 is better suited for hard or soft shafts, but hard shaft surfaces tend to have better holding times. Starting at loads of 145 psi, wear increases measurably and continuously.

Chemical Resistance

iglie® N54 plastic bushings have good resistance to chemicals. They are resistant to most lubricants. iglide® N54 is not impaired by most weak organic and inorganic acids and bases.

Radioactive rays

iglide® N54 plastic bushings can be used with restrictions when exposed to radiation. They are resistant up to a radiation intensity of 1 x 104 Gy.

UV-resistant

iglide® N54 plastic bushings are resistant to UV rays.

Vacuum

The low water elements degas in the vacuum. Applications under vacuum conditions are possible with restrictions.

| Medium | Resistance |

|---|---|

| Alcohols | + to 0 |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | 0 to + |

| Strong acids | - |

| Weak alkaline | + |

| Strong alkaline | 0 |

| + resistant 0 conditionally resistant - non-resistant | |

| All specifications at room temperature (+68 °F) | |

| Chemical resistance of iglide® N54 |

Electrical properties

iglide® N54 plastic bushings are electrically insulating.

| Specific volume resistance | Surface resistance |

|---|---|

| < 1013 Ωcm | < 1011 Ω |

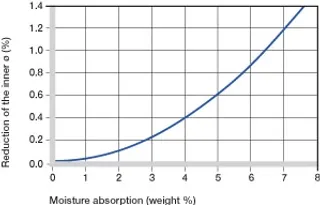

Influence of moisture absorption on iglide® N54 plastic bushings

Moisture Absorption

The moisture absorption of iglide® N54 plastic bushings is about 1.6% in standard climatic conditions. The saturation limit in water is 3.6 %.

Installation tolerances

iglide® UW plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9).

The bushings are designed for press-fit in a housing with h7 tolerance. After the installation in a housing with nominal diameter, the inner diameter of the bushing automatically adjusts to the E10 tolerance.

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® N54 E10 [mm] | Housing H7 [mm] |

|---|---|---|---|