Change Language :

igus® materials in the test versus PTFE foils significantly more wear-resistant

Wear of machine parts depends on diverse influence factors. Thus designers are often confronted with the challenge of deciding between various material alternatives. With regard to wear behavior, igus® has now also compared its bar stock material iglide® A160, as well as its tribotape® material iglide® V400 on various counter partners with PTFE foils.

The trials were executed under the following test parameters:

Foils: iglide® A160, iglide® V400, and PTFE

Counter partners: Stainless steel, glass (in this case: Soda-lime glass, PET, and paper

Load: 2.25 lb

Speed: 0.722 ft/s

Temperature: 73ºF

The tests with the PTFE foil show an extremely high rate of wear against all counter partners. Compared with the PTFE foil, the two materials, iglide® A160 and iglide® V400, show significantly lower wear rates.

Bar stock made of iglide® A160

iglide® A160 by the unit for free design. More wear resistant in comparison with the PTFE foil

Bar stock made of iglide® A160

Wear resistant at high temperatures

Extreme wear resistance with soft shafts and in high temperatures up to +392°F

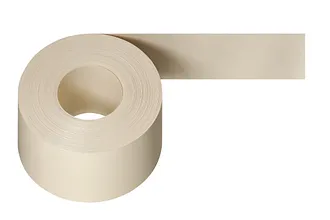

iglide® V400Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert