Change Language :

Wear testing for customer

iglide® J350 against PPA GF-30 shafts

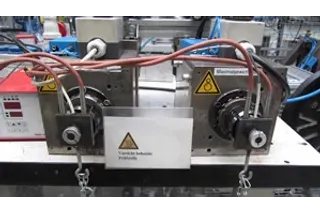

The two test rigs used to conduct the tests. The installed bearing supports can be heated to permit temperature control.

The iglide® J350 material was tested for a customer from the automobile industry. In addition to the required temperature and media-resistance, the primary reasons were good wear-resistance against the PPA GF-30 plastic shaft used by the customer.

The igus® test lab conducted a wear test using the customer's original shaft material under the following conditions to explicitly test the good suitability of iglide® J350:

Test configuration

Load: 16 N

Pivot angle: 20°

Speed: 2 Hz ≙ 0,022 ft/s

Temperature: 50% of time 302°F; 30% of time 248°F; 20% of time room temperature

Operating time: > 800.000 cycles ≙about 1,87 miles

Test results

The bearings exhibit very little signs of friction.

Shaft wear patterns

Conclusion:

The iglide® J350 bearings exhibited only very little wear at 3.4µm/km. No wear was measured on the PPA GF30 shaft.