Change Language :

iglide® D - Material data

Materials table

General features

Unit

iglide® D

Test method

Density

g/cm³

1.40

Color

Green

Max. moisture absorption at 73° F/50% R. H.

Wt.-%

0.3

DIN 53495

Max. moisture absorption

Wt.-%

1.1

Coefficient of surface friction, dynamic, against steel

µ

0.08 - 0.26

p x v value, max. (dry)

psi x fpm

8,700

Mechanical properties

Modulus of elasticity

psi

290,100

DIN 53457

Tensile strength at 68° F

psi

10,440

DIN 53452

Compressive strength

psi

10,150

Maximum recommended surface pressure (68° F)

psi

3,336

Shore D hardness

78

DIN 53505

Physical and thermal properties

Upper long-term application temperature

°F

194

Upper short-term application temperature

°F

230

Lower application temperature

°F

-58

Heat conductivity

[W/m x K]

0.25

ASTM C 177

Coefficient of thermal expansion (at 73° F)

[K-1 x 10-5 ]

11

DIN 53752

Electrical properties

Specific forward resistance

Ωcm

> 1014

DIN IEC 93

Surface resistance

Ω

> 1014

DIN 53482

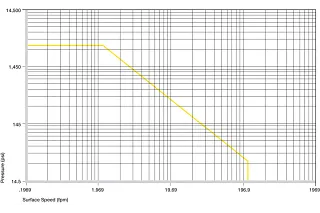

Permitted p x v values

For iglide® D plastic bushings with 1 mm wall thickness in dry operation against a steel shaft, at 68° F, installed in a steel housing.

The development of the iglide® D as a bushing material placed high performances and very low costs high up on the application profile. It should achieve particularly low coefficients of friction in the dry operation at high speeds. Bushings made of iglide® D are selectively supported by a combination of solid lubricants. The material containing silicon achieves extremely low coefficients of friction in dry operation and runs largely free of stick-slip effects.

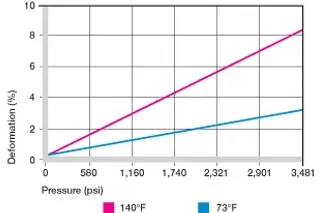

Figure 24.2: Deformation under load and temperatures

Surface pressure

iglide® D plastic bushings were developed mainly for low to medium radial loads. Figure 24.2 shows the elastic deformation of iglide® D with radial loads. Under the maximum recommended surface pressure of 3,336 psi, the deformation amounts to about 3%. A plastic deformation can be negligible up to this value. It is however also dependent on the period of exposure.

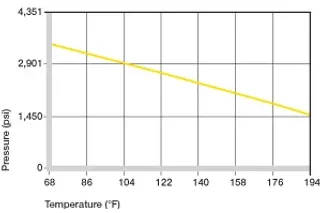

Figure 24.3: Maximum recommended surface pressure dependent on the temperature

Temperatures

The short-term permitted maximum temperature is 230° F, and the long-term application temperature is 194° F. With increasing temperatures, the compressive strength of iglide® D plastic bushings decreases. Fig. 24.3 clarifies this connection.

The temperatures prevailing in the bushing system have an influence on the bushing wear. The wear rises with increasing temperatures.

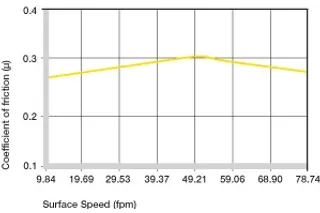

Figure 2.4: Coefficients of friction dependent on the surface speed, p = 108 psi

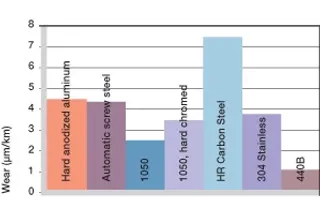

Fig. 2.7: Wear, rotating application with different shaft materials, load p = 108 psi, v = 98.5 fpm

Shaft materials

The graphs display a summary of the results of tests with different shaft materials conducted with bushing made of iglide® D.

In the low load range, the hard chromed shaft is the most suitable material for iglide® D plastic bushings. At loads greater than 290 psi, shafts made of 1050 hardened and ground steel as well as 304 stainless steel increase wear resistance.

For oscillating operation, the 1050 hardened and ground steel shafts and the 304 stainless steel shafts can be used in the low load range.

Please contact us in case the shaft material scheduled by you is not included in this list.

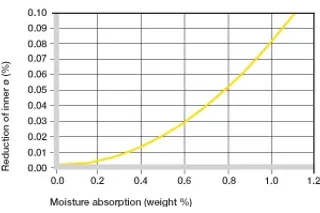

Figure 24.10: Influence of moisture absorption of iglide® D plastic bushings

Radioactive rays

iglide® D plastic bushings are radiation resistant up to a radioactive intensity of 3 x 10² Gy.