Change Language :

iglide® UW - Material data

Materials table

General features

Unit

iglide® UW

Test method

Density

g/cm³

1.52

Color

Black

Max. moisture absorption at 73° F/50% R. H.

Wt.-%

0.2

DIN 53495

Max. moisture absorption

Wt.-%

0.8

Coefficient of friction, dynamic against steel

µ

0.15 - 0.35

p x v value, max. (dry)

psi x fpm

2,800

Mechanical properties

Modulus of elasticity

psi

1,392,000

DIN 53457

Tensile strength at 68° F

psi

13,050

DIN 53452

Compressive strenght

psi

10,150

Permissible static surface pressure (68° F)

psi

5,802

Shore D hardness

78

DIN 53505

Physical and thermal properties

Upper long-term application temperature

°F

194

Upper short-term application temperature

°F

230

Lower application temperature

°F

-58

Thermal conductivity

[W/m x K]

0.60

ASTM C 177

Coefficient of thermal expansion (at 73° F)

[K-1 x 10-5 ]

6

DIN 53752

Electrical properties

Specific volume resistance

Ωcm

< 10 5

DIN IEC 93

Surface resistance

Ω

< 10 5

DIN 53482

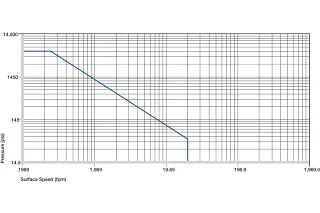

Permitted p x v values

For iglide® UW plastic bushings with 0.039 inches wall thickness in dry operation against a steel shaft, at 68° F, installed in a steel housing.

iglide® UW was developed for underwater applications in which the maximum temperatures clearly lie below 212° F. For application temperatures above this limit, the bushings made of iglide® UW500 are available. Though iglide® UW was developed for application in liquids, it is also suitable for dry operation. This one is particularly important in applications that call for both dry and wet operations. These applications can be seen often in practice. The features of the bushings made of iglide® UW described in this section apply to the dry operation. Unless it is expressly mentioned otherwise.

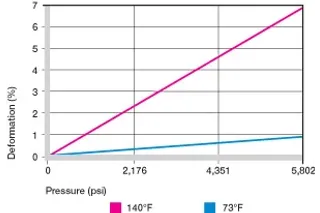

Deformation under load and temperatures

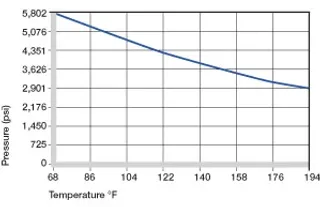

Compressive Strength

The graph shows the maximum recommended surface pressure for various temperatures. iglide® UW plastic bushings are suitable for application under low to medium loads. High loads occur rather seldom in underwater applications.

The wear increases from a radial load of 725 psi upward.

Maximum recommended surface pressure dependent on the temperature

Temperatures

As mentioned earlier, the iglide® UW plastic bushings are recommended rather for the low temperature range. Frictional heat should be taken into account in the dry operation from a maximum 194° F temperature at the bushing position.

In underwater application the medium serves to put down the heat, which temperature is primarily important.

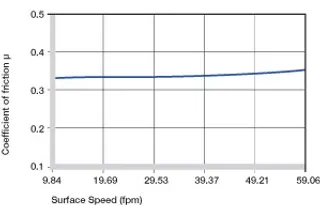

Coefficients of friction dependent on the surface speed, p =108 psi

Friction and wear

In underwater application the coefficients of friction are, as is known, essentially lower than in dry operation through the lubrication. In dry operation the coefficient of friction rises up to 0.4 with low loads. With higher loads, it lowers to 0.1.

The surface finishes of the shafts should not be extremely smooth in order to prevent a high adhesion effect and the entailing increases in the coefficient of friction.

Please contact us for the specifications of shaft surface finishes in underwater applications.

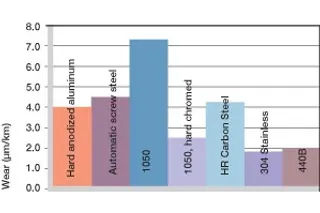

Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

With low loads in rotary motion, the influence of the shaft materials given in the graph on the iglide® UW plastic bushings is relatively low. The graph shows that this strongly varies with increasing loads.

Call your igus® consultant for queries on a special counter partner.

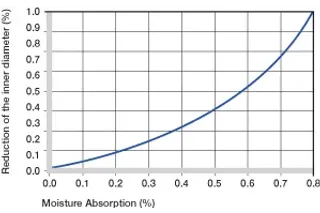

Influence of moisture absorption of iglide® UW plastic bushings

Radioactive rays

iglide® UW plastic bushings are radiation resistant up to a radioactive intensity of 3 x 10² Gy.