Change Language :

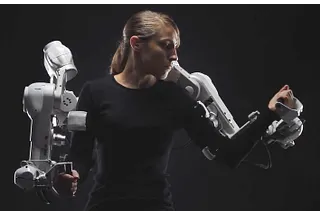

Linear Guide Rails & Plastic Bearings for Exoskeletons

Profile

- What was needed: Linear rails and plain bearings that can be adjusted as simply and easily as possible to accommodate different body sizes.

- Requirements: All components had to be easy to adjust, clean and hygienic

- Products used: drylin® T linear rails and bearings, drylin® R linear shafts and bearings, and iglide® plain bearings

- Industry: medical technology

- Success for the customer: Easy to adjust unit without dirt on fingers, clothes or objects. Very light but strong components that makes it easy for staff and patients to adjust.

Rail guides of the drylin® series T and drylin® R round shaft guide allows easy adjustment of the system to the patient's body size, arm length and shoulder width. Due to the absence of external lubricants, the bearings are

- completely maintenance-free

- Clean and hygienic

- Lightweight due to plastic and aluminium

and thus optimally suited for medical technology. The design is so compact that it can be integrated into the slim design of the robot.

"Thanks to the use of the igus® polymer bearing technology, the exoskeleton can now be adapted to the patient within seconds," enthuses Rohit John Varghese, Head of Research & Development at Harmonic Bionics.

drylin® T is THE linear guide system from igus® - clean, robust, durable and directly available.

Products Used:

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert