Change Language :

drylin® ZLW-OD belt drive system in new size 16

… reversing …

The new drylin® belt drive system ZLW-OD in installation size 1660 completes the series of reversing linear axes. A robust build based on the self-lubricating drylin® W system, aluminium cross traverses and grooved ball bearings in the support ends enable extremely fast reverse positioning with a maximum stroke of 3,000 mm. The axis can be configured, ordered and delivered with the drylin® NEMA stepper motors for motorized positioning.

Self-lubricating linear guide based on drylin® W

Individual stroke lengths up to max. 3,000 mm

Radial loads up to 200 N

drylin® E stepper motors (with or without encoder and/or brake) available

Delivery includes angle flange for fixing

Typical applications:Handling and automation, vending machines, automaticstorage and retrieval machines

Orientation angle flange

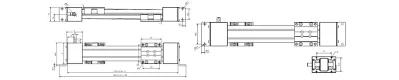

Dimensions [mm]

| Part No. | A | Al | H | Ht | E2 | E3 | L | R | f | lt | sg | ha | lz | Stroke length | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| -0,3 | ±0,15 | ±0,15 | ±0,15 | ±0,15 | |||||||||||

| ZLW-1660-OD-02 | 104 | 100 | 70 | 70 | 86 | 82 | 248 | 58 | 0 | 79 | M8 | 35 | 36 | 3000 | Request |

| ZLW-1660-OD-03 | 104 | 100 | 70 | 70 | 86 | 82 | 248 | 58 | 0 | 79 | M8 | 35 | 36 | 3000 | Request |

| ZLW-1660-OD-04 | 104 | 100 | 70 | 70 | 86 | 82 | 248 | 58 | 0 | 79 | M8 | 35 | 36 | 3000 | Request |

| Part No. | l2 | d2 | d | T1 | T2 | WS | W1 | W2 | dW1 | IW | AW | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| h9 | ±0,15 | ±0,15 | ||||||||||

| ZLW-1660-OD-02 | 20 | 14 | M5 - 10 deep | 65 | 60 | 5 | 15 | 54 | 8,5 | 328 | 114 | Request |

| ZLW-1660-OD-03 | 20 | 14 | M5 - 10 deep | 65 | 60 | 5 | 15 | 88 | 8,5 | 328 | 75 | Request |

| ZLW-1660-OD-04 | 20 | 14 | M5 - 10 deep | 65 | 60 | 5 | - | - | - | 248 | 70 | Request |