Change Language :

Abrasion-optimized high-speed glide bar

5 times more durable than conventional glide bars

In the case of very fast gliding applications, the glide bars in the super aluminium troughs have been a potential weak point. They wear faster than the more abrasion-resistant chains. For these applications, an abrasion-optimised, injection-moulded glide bar has now been developed. This is much more durable for the same price and will be used in future in all matching trough sizes.

Tech up

Cost down

Proof

Sustainability

Technical details

| Part No. | Aluminium SuperTrough | Part No. | Aluminium SuperTrough | |

|---|---|---|---|---|

| GB.21.09.500* | 971.31.SLH | GB.31.500** | 973.31.SLH | |

| GB.21.09.500* | 972.02.31.SLH | GB.31.500** | 974.31.SLH | |

| GB.21.09.500* | 972.32.SLH | GB.31.500* | 975.31.SLH | |

| GB.21.13.500* | 972.31.SLH | |||

| Can be shipped starting in the spring of 2020 | **Introduced 10/2019 |

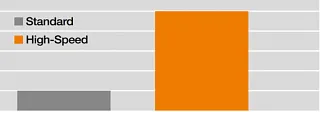

Glide bar service life comparison – high-speed glide bar vs. standard glide bar

Tested high-speed glide bar wear resistance

Comparison tests of real customer applications have shown that, for highly dynamic applications, the new GB.31.500 glide bars exhibit wear that is lower by more than a factor of five. This reduces glide bar maintenance costs to a minimum. Only when the energy chain has reached its wear limit does the glide bar require inspection. The new glide bar has no direct influence on the service life of the e-chain® itself.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert