Change Language :

After 1,591 miles test with carbon fiber shafts, it is clear: iglide® J260 is best suited for carbon fiber shafts

It becomes increasingly important nowadays to install lightweight and strong materials precisely where masses are moved, so that weight and thereby energy and money can be saved.

In recent months, the igus® GmbH has stepped up the testing of carbon fiber shafts in conjunction with various iglide® bearings. The determined wear rates of the individual materials vary very much – and sometimes surprise the igus® material experts as well. Not every iglide® material, which runs continuously on metallic shafts, also show above-average performance on carbon fiber shafts.

The combination of carbon fiber shafts and plastic plain bearings sounds too specific and non-combinable at first. But carbon fiber shafts are becoming increasingly interesting for numerous applications due to their material properties. They are characterized mainly by low weight and high bending strength.

In recent months, 25 different high-performance polymers were tested in combination with carbon fiber shafts in the igus® test lab to find out which combination gives the best value in terms of wear and tear. For this purpose, a total of 1,591 miles were covered on a test rig for linear short stroke.

Here are some details from the test:

- Radial load on the bearings: 145 psi

- Speed of the shaft in linear motion: 0.328 ft/s

- Temperature: 73ºF

Conclusion:

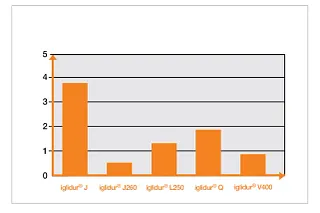

Short linear stroke against carbon-fiber shafts

P= 1MPa (145 psi), v= 0.1m/s (0,328 ft/s), T= 23°C (73ºF)

y-axis: Wear rate [μm/km]

After 1,591 miles test with carbon fiber shafts it is clear - iglide® J260 with a wear rate of 0.53 µm/km is best suited for carbon fiber shafts.

Short linear stroke against carbon-fiber shafts

P= 1MPa (145 psi), v= 0.1m/s (0,328 ft/s), T= 23°C (73ºF), y-axis: Wear rate [μm/km]

More information:

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert