Change Language :

iglide® H2 - Material data

| General features | Unit | iglide® H2 | Test method |

|---|---|---|---|

| Density | g/cm3 | 1.72 | |

| Color | Brown | ||

| Max. moisture absorption at 73° F/50% R. H. | Wt.-% | < 0.1 | DIN 53495 |

| Max. moisture absorption | Wt.-% | 0.2 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.07 - 0.3 | |

| p x v value, max. (dry) | psi x fpm | 16,500 | |

| Mechanical properties | |||

| Modulus of elasticity | psi | 1,494,000 | DIN 53457 |

| Tensile strength at 68 ° F | psi | 30,460 | DIN 53452 |

| Compressive strength | psi | 15,810 | |

| Permissible static surface pressure (68° F) | psi | 15,950 | |

| Shore D hardness | 88 | DIN 53505 | |

| Physical and thermal properties | |||

| Upper long-term application temperature | °F | 392 | |

| Upper short-term application temperature | °F | 464 | |

| Lower application temperature | °F | -40 | |

| Thermal conductivity | [W/m x K] | 0.24 | ASTM C 177 |

| Coefficient of thermal expansion (at 73° F) | [K-1 x 10-5 ] | 4 | DIN 53752 |

| Electrical properties | |||

| Specific volume resistance | Ωcm | > 1015 | DIN IEC 93 |

| Surface resistance | Ω | > 1014 | DIN 53482 |

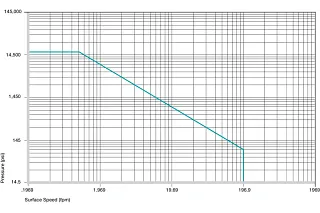

Permitted p x v values

For iglide® H2 plastic bushings with 0.03937 in wall thickness in dry operation against a steel shaft, at 68° F , installed in a steel housing.

In applications with the iglide® H2 plastic bushings, economical aspects are in focus. It is the first time that it is possible to offer such a high-performance bushing for large volume applications with these technical advantages at such a low price: Temperatures till 392° F, permitted surface pressure till 110 N/mm, and excellent chemical resistance. A mixture of solid lubricants lowers the coefficient of friction and supports the wear resistance. The iglide® H2 plastic bushings are self-lubricating and suitable for all motions.

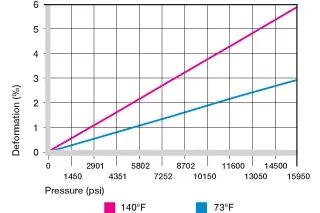

Figure 26.2: Deformation under load and temperatures

Surface pressure

Figure 26.2 shows the elastic deformation of iglide® H2 with radial loads. At the recommended surface pressure of 15,950 psi, the deformation at room temperature is below 3%. The values for bending and compressive strengths lie above those of iglide® H at room temperature.

Permitted surface speed

In the development of iglide® H2, cost aspects and mechanical stability were in focus. The permitted surface speeds of this plastic bushings are rather low, which primarily permits an application with slow movements or in intermittent service.

| fpm | rotating | oscillating | linear |

|---|---|---|---|

| continuous | 177 | 118 | 492 |

| short-term | 196 | 137 | 590 |

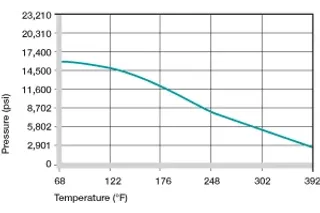

Figure 26.3: Maximum recommended surface pressure dependent on the temperature

Temperatures

iglide® H2 is an extremely temperature-resistant material. The short-term permitted maximum temperature is 464° F, and this enables the iglide® H2 plastic bushings to be subjected, for instance to a paint drying process without further load. With increasing temperatures, the compressive strength of iglide® H2 plastic bushings however decreases more strongly than in iglide® H. Fig. 26.3 clarifies this connection.

The temperatures prevailing in the bushings system also have an influence on the bushing wear. The wear rises with increasing temperatures.

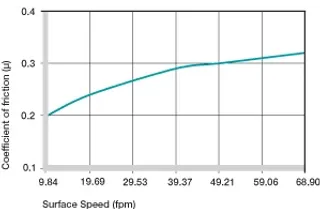

Figure 2.4: Coefficients of friction dependent on the surface speed, p = 108 psi

Friction and wear

The diagrams clarify how the coefficients of friction of iglide® H2 plastic bushings alter with different surface speeds, loads and surface finishes.

Paired with hardened steel shafts, the friction of the iglide® H2 plastic bushings reduces sharply and in the high load range attains (> 4,351 psi).

The hardness and brittleness of the material are the reason for the sensitivity of the iglide® H2 plastic bushings with coarse shafts; smooth shafts (4 rms) in contrast do not increase the friction of the systems.

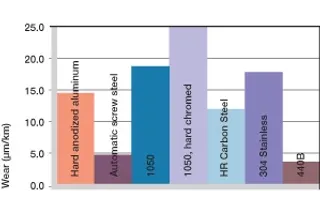

Figure 26.8: Wear, rotating application with different shaft materials, p = 108 psi, v = 98 fpm

Shaft materials

Regarding the wear resistance of combinations with iglide® H2, it must be indicated once again that this plastic bushings was developed for statically high mechanical stability. The wear resistance however does not attain, with none of the bushing-shaft combinations, the values of iglide® H370 with the corresponding shaft.

When the iglide® H2 plastic bushings are used, they should not be combined with hard-chromed shafts. Shafts made from 1050 hardened and ground steel and 303 stainless are essentially better, as shown in the graphs.

In case you would like to use shaft materials not listed in this comparison, call us. Results for many other shaft-bearing combinations are available.

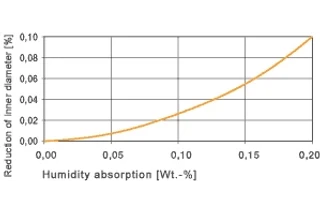

Installation tolerances

iglide® H2 plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9).

After the installation in a housing bore with H7 tolerance, the inner diameter of the bushing automatically adjusts to F10 tolerance.

| Diameter d1 [inch] | Shaft h9 [inch] | iglide® H2 F10 [inch] |

|---|---|---|

| Up to 0.03937 | 0 - 0.0009843 | +0.0002362 + 0.0018110 |

| > 0.1181 to 0.2362 | 0 - 0.0011811 | +0.0003937 + 0.0022835 |

| > 0.2362 to 0.3937 | 0 - 0.0014173 | +0.0005118 + 0.0027953 |

| > 0.3937 to 0.7087 | 0 - 0.0016929 | +0.0006299 + 0.0033858 |

| > 0.7087 to 1.1811 | 0 - 0.0020472 | +0.0007874 + 0.0040950 |

| > 1.1811 to 1.9685 | 0 - 0.0024409 | +0.0009843 + 0.0049212 |

Chemical resistance

iglide® H2 plastic bushings have a good resistance against chemicals. They are resistant to most lubricants. The iglide® H2 is not affected by most weak organic and inorganic acids. The humidity absorption of iglide® H2 plastic bushings is about 0.1% in standard climatic conditions. The saturation limit in water is 0,2%. iglide® H2 is therefore the ideal material for wet areas.

Radioactive rays

iglide® H2 withstands both the neutron and gamma particle radiations without noticeable loss to its excellent mechanical properties. iglide® H2 plastic bushings are radiation resistant up to a radioactive intensity of 2 x 10² Gy.

UV-resistant

iglide® H2 plastic bushings alter under the influence of UV rays and other climatic influences. The surface becomes coarser, and the compressive strength declines. Therefore the use of iglide® H2 in applications directly exposed to climatic conditions should be tested.

Vacuum

The low water elements degas in the vacuum. The use in vacuum is possible.

| Medium | Resistance |

|---|---|

| Alcohol | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | + to 0 |

| Strong acids | + to - |

| Weak alkaline | + |

| Strong alkaline | + |

| + resistant 0 conditionally resistant - non-resistant |

Electrical properties

Unlike iglide® H and iglide® H370, iglide® H2 is electrically insulating.

| Specific volume resistance | Surface resistance |

|---|---|

| > 1015 Ωcm | > 1014 Ω |

Delivery program

The iglide® H2 plastic bushings are manufactured according to order specifications. Please contact us for applications with large numbers of bushings made of iglide® H2 as alternative to iglide® H and H370.