Change Language :

iglide® B - Material data

Materials table

General features

Unit

iglide® B

Test method

Density

g/cm³

1,15

Color

Gray

Max. humidity absorption at 23° C/50% R. H.

Wt.-%

1,0

DIN 53495

Max. water absorption

Wt.-%

6,3

Mechanical properties

Bending E-module

MPa

1.750

DIN 53457

Bending strength at 20° C

MPa

55

DIN 53452

Maximum recommended surface pressure (20° C)

MPa

40

Shore D hardness

69

DIN 53505

Physical and thermal properties

Upper long-term application temperature

°C

100

Upper short-term application temperature

°C

130

Upper short-term ambient temperature1)

°C

150

Lower application temperature

°C

-40

Electrical properties

Specific forward resistance

Ωcm

> 1010

DIN IEC 93

Surface resistance

Ω

> 10 9

DIN 53482

- Without additional load; no gliding movement; relaxation not excluded.

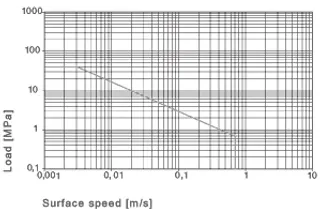

Permitted p x v values

For iglide® B bearings with 1 mm wall thickness in dry operation against a steel shaft, at 20° C, installed in a steel housing.

Vibration dampening and the separation of impact sound were the focus in the development of iglide® B.

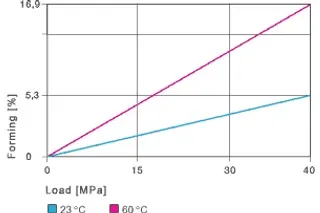

Figure 22.2: Deformation under load and temperatures

Surface pressure

The compressive strength of the iglide® B bearings is on the one hand low, but on the other, is an important property of the bearing. They are mainly used where vibration dampening and acoustic separation are required.

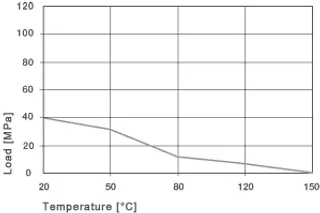

Figure 22.3: Maximum recommended surface pressure dependent on the temperature

Temperatures

The operating temperature of the iglide® B bearings is limited to 100° C. From 50° C onward, the very soft bearing should be mechanically fastened, so that the danger of bushings creeping out of the bores is avoided. The wear resistance too declines disproportionately from 70° C.

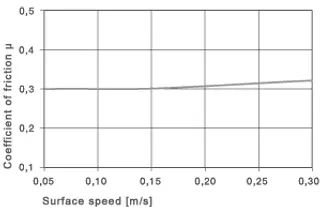

Figure 2.4: Coefficients of friction dependent on the surface speed, p = 0.75 MPa

Friction and wear

The iglide® B bearings assume a center position in wear resistance. As far as the bearing load is not too high, the attained coefficients of wear are pretty good. An increase in load results in a disproportionate increase in abrasion.

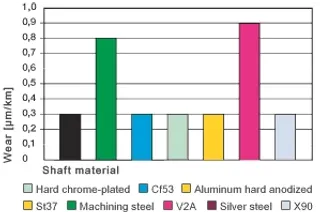

Fig. 2.7: Wear, rotating application with different shaft materials, load p = 0.75 MPa, v = 0.5 m/s

Shaft materials

The influence of the shaft is not very large in wear resistance.

Figures 22.7 and 22.8 clarify that very similar wear data are attained with different shaft materials. If high operational performances are expected, the bearing load should not be too high.

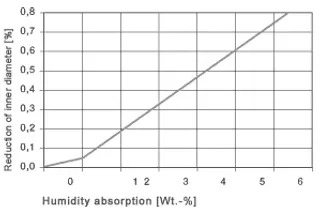

Figure 22.10: Influence of humidity absorption of iglide® B bearings

Radioactive rays

iglide® B bearings are radiation resistant up to a radioactive intensity of 3 x 10² Gy.