Change Language :

iglide® H4 - Material data

Materials table

| General features | Unit | iglide® H4 | Test method |

|---|---|---|---|

| Density | g/cm3 | 1,79 | |

| Color | Brown | ||

| Max. moisture absorption at 73° F/50% R. H. | Wt.-% | 0,1 | |

| Max. moisture absorption | Wt.-% | 0,2 | |

| Coefficient of friction, dynamic against steel | µ | 0.08 - 0.25 | |

| p x v value, max. (dry) | psi x fpm | 19,500 | |

| Mechanical properties | |||

| Modulus of elasticity | psi | 1,088,000 | DIN 53457 |

| Tensile strength at 68° F | psi | 17,400 | DIN 53452 |

| Compressive strength | psi | 7,252 | |

| Permissible static surface pressure (68° F) | psi | 9,427 | |

| Shore D hardness | 80 | DIN 53505 | |

| Physical and thermal properties | |||

| Upper long-term application temperature | °F | 392 | |

| Upper short-term application temperature | °F | 464 | |

| Lower application temperature | °F | -40 | |

| Thermal conductivity | W/m x K | 0.24 | ASTM C 177 |

| Coefficient of thermal expansion (at 73° F) | K-1 x 10-5 | 5 | DIN 53752 |

| Electrical properties | |||

| Specific volume resistance | Ωcm | > 1013 | DIN IEC 93 |

| Surface resistance | Ω | > 1012 | DIN 53482 |

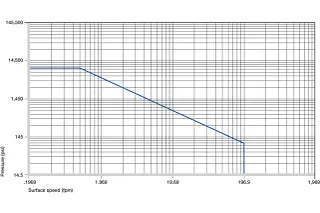

Permitted p x v values

For iglide® H4 plastic bushings running dry against a steel shaft. at 68° F.

iglide® H4 plastic bushings stand for high carrying capacity, good abrasion resistance and good temperature resistance, besides the obvious economic factors. Temperatures up to 392° F, permitted surface pressure up to 9,427 psi, and excellent chemical resistance are only some of the essential attributes. Solid lubricants lower the coefficient of friction and support the wear resistance, which was essentially improved compared to the likewise cost-efficient iglide® H2 plastic bushings. iglide® H4 plastic bushings are self-lubricating and suitable for all motions.

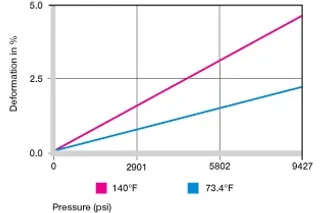

Figure 13.2: Deformation under load and temperatures

Surface pressure

Figure 13.2 shows the elastic deformation of iglide® H4 with radial loads. iglide® H4 has excellent elasticity values. This is beneficial in applications with edge loads and is the reason for a higher mechanical loss factor that indicates the vibration dampening capacity of a material. If a high static compressive strength is required, the other iglide® H plastic bushings types are beneficial.

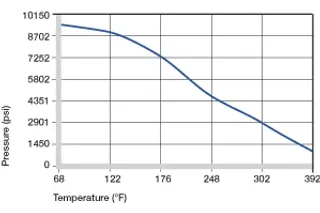

Figure 13.3: Maximum recommended surface pressure dependent on the temperature

Temperatures

iglide® H4 is a temperature-resistant material. The short-term permitted maximum temperature is 464° F, and this enables the iglide® H4 plastic bushings to be subjected for instance, to a paint drying process without further load. With increasing temperatures, the compressive strength of iglide® H4 plastic bushings however decreases.

Fig. 13.3 clarifies this connection. The additional frictional heat in the bearing system should be considered in the temperatures.

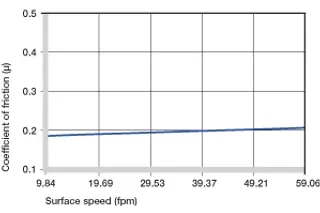

Figure 2.4: Coefficients of friction dependent on the surface speed, p = 108 psi

Friction and wear

As said earlier, the coefficient of friction of the iglide® H4 plastic bushings is very low. However it must be noted that an extremely coarse gliding partner can increase the friction. We recommend a shaft roughness range of 4 to 16 rms. The coefficient of friction of the iglide® H4 plastic bushings is dependent on the surface speed only to a minor extent. The influence of the load is greater; an increase in load lowers the coefficient of friction up to 0.08.

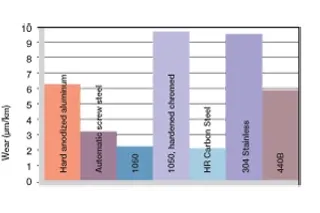

Fig. 2.7: Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

In many of the usable shaft materials, the iglide® H4 is the economical alternative to many other high-temperature bushings. The important thing is however the selection of the suitable shaft material. It cannot be generally stated that iglide® H4 is better suited for hard or soft shafts. Tests have however shown that pivoting motions yield better wear data. In rotating applications, the wear increases markedly from pressures of 1450 psi.

iglide® H4 plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9).

After the installation in a housing bore with H7 tolerance, the inner diameter of the bearing automatically adjusts to F10 tolerance.

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® H4 F10 [mm] |

|---|---|---|

| Up to 0.5 | 0 - 0,025 | +0,006 + 0,046 |

| > 3 to 6 | 0 - 0,030 | +0,010 + 0,058 |

| > 6 to 10 | 0 - 0,036 | +0,013 + 0,071 |

| > 10 to 18 | 0 - 0,043 | +0,016 + 0,086 |

| > 18 to 30 | 0 - 0,052 | +0,020 + 0,104 |

| > 30 to 50 | 0 - 0,062 | +0,030 + 0,150 |

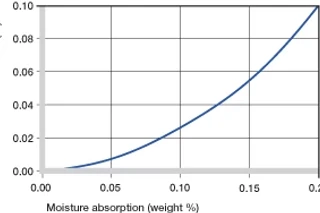

Chemical resistance

iglide® H4 plastic bushings have a good resistance against chemicals. They are resistant to most lubricants. The iglide® H4 is not affected by most weak organic and inorganic acids.

The moisture absorption of iglide® H4 plastic bushings is about 0.1% in standard climatic conditions. The saturation limit in water is 0,2%. iglide® H4 is therefore the ideal material for wet areas.

Radioactive rays

iglide® H4 withstands both the neutron and gamma particle radiations without noticeable loss to its excellent mechanical properties. iglide® H4 plastic bushings are radiation resistant up to a radioactive intensity of 2 x 10² Gy.

UV-resistant

iglide® H4 plastic bushings alter under the influence of UV rays and other climatic influences. The surface becomes coarser, and the compressive strength declines. Therefore the use of iglide® H4 in applications directly exposed to climatic conditions should be tested.

Vacuum

The low water elements degas in the vacuum. The use in vacuum is possible.

| Medium | Resistance |

|---|---|

| Alcohol | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | + to 0 |

| Strong acids | + to - |

| Weak alkaline | + |

| Strong alkaline | + |

| + resistant 0 conditionally resistant - non-resistant |

Electrical properties

Unlike iglide® H and iglide® H370, iglide® H4 is electrically insulating.

| Specific forward resistance | Surface resistance |

|---|---|

| > 1013 Ωcm | > 1012 Ω |