Change Language :

iglide® L250 - Material data

Materials table

General features

Unit

iglide® L250

Test method

Density

g/cm³

1.50

Color

Beige

Max. moisture absorption at 73° F/50% R. H.

Wt.-%

0.7

DIN 53495

Max. moisture absorption

Wt.-%

3.9

Coefficient of friction, dynamic against steel

µ

0.08 - 0.19

p x v value, max. (dry)

psi x fpm

11,500

Mechanical properties

Modulus of elasticity

psi

282,800

DIN 53457

Tensile strength at 68° F

psi

9,718

DIN 53452

Compressive Strength

psi

6,817

Maximum recommended surface pressure (68° F)

psi

6,527

Shore D hardness

68

DIN 53505

Physical and thermal properties

Upper long-term application temperature

°F

194

Upper short-term application temperature

°F

356

Lower application temperature

°F

-40

Thermal conductivity

[W/m x K]

0.24

ASTM C 177

Coefficient of thermal expansion (at 73° F)

[K-1 x 10-5 ]

10

DIN 53752

Electrical properties

Specific volume resistance

Ωcm

> 1010

DIN IEC 93

Surface resistance

Ω

> 1011

DIN 53482

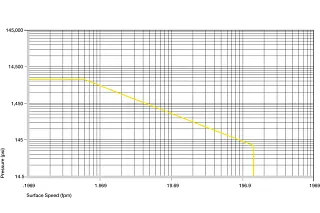

Permissible p x v values for iglide® L250 running dry against a steel shaft, at 68° F.

Permitted p x v values

For iglide® L250 plastic bushings with 0.03 inches (1 mm) wall thickness in dry operation against a steel shaft, at 68° F, installed in a steel housing.

iglide® L250 is a bushing material for high rotary speeds, fast gliding movements and super coefficients of friction. The iglide® L250 material can feature these advantages particularly with low loads. Applications which feature these advantages are fans, small motors, fast-running sensors or the magnet technology.

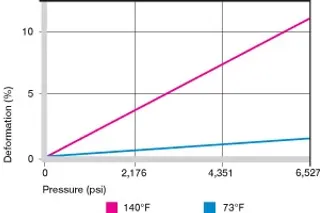

Deformation under load and temperatures

Surface pressure

With increasing temperatures, the compressive strength of iglide® L250 plastic bushings decreases. The graph shows this inverse relationship. However, at the long term maximum temperature of +194 °F the permissible surface pressure is almost 2901 psi.

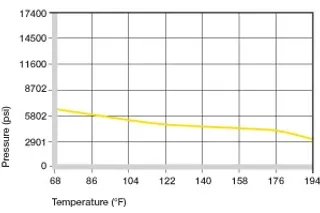

Maximum recommended surface pressure dependent on the temperature

Temperatures

The iglide® L250 plastic bushings can be used in temperatures from -40° F up to 194° F. The short-term maximum temperature is 356° F. Note that a mechanical securing of the bushing is recommended from temperatures of 131° F. Higher temperatures can also cause the bushing to lose its press-fit seating and move in the housing.

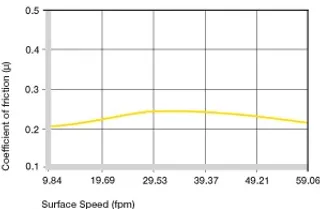

Coefficients of friction of iglide® L250 as a function of the running speed; p = 108 psi

Friction and wear

Low coefficients of friction are a big influence on the excellent characteristics of iglide® L250 plastic bushings. The best pairing of iglide® L250 is with 304 stainless steel shafts where coefficient of friction of 0.14 are already attained at low loads. Coefficients of friction below 0.1 have already been measured for values below 1,450 psi. In order to convey the excellent wear values to the application, loads in excess of 725 psi should be avoided.

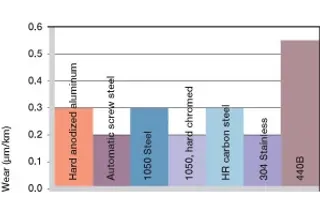

Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

As shown in the graphs, a variety of shafts can be used at low loads and low rotation. The good coefficients of friction are maintained across a wide range of recommended shaft roughness values. With regards to loads greater than 145 psi the shaft material selection becomes more important.

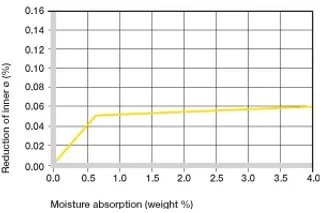

Influence of moisture absorption of iglide® L250 plastic bushings

Radioactive rays

iglide® L250 plastic bushings are radiation resistant up to a radioactive intensity of 3 x 104 Gy. Higher radiation affects the material and may potentially lead to a notable lowering of value of an important mechanical property.