Change Language :

iglide® T220 - Material data

Materials table

General features

Unit

iglide® T220

Test method

Density

g/cm³

1.28

Color

White

Max. moisture absorption at 73° F/50% R. H.

Wt.-%

0.3

DIN 53495

Max. water absorption

Wt.-%

0.5

Coefficient of friction, dynamic against steel

µ

0.20 - 0.32

p x v value, max. (dry)

psi x fpm

8,000

Mechanical properties

Modulus of elasticity

psi

261,100

DIN 53457

Tensile strength at 68° F

psi

9,427

DIN 53452

Compressive strength

psi

7,977

Maximum recommended surface pressure (68° F)

psi

5,802

Shore D hardness

76

DIN 53505

Physical and thermal properties

Upper long-term application temperature

°F

212

Upper short-term application temperature

°F

320

Min. application temperature

°F

-40

Thermal conductivity

[W/m x K]

0.24

ASTM C 177

Coefficient of thermal expansion (at 73° F)

[K-1 x 10-5 ]

11

DIN 53752

Electrical properties

Specific volume resistance

Ωcm

> 1010

DIN IEC 93

Surface resistance

Ω

> 1010

DIN 53482

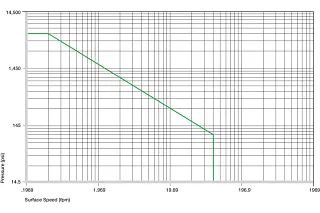

Permitted p x v values

For iglide® T220 plastic bushings with 0.039 inches wall thickness in dry operation against a steel shaft, at 68° F, installed in a steel housing.

iglide® T220 is a special material for application in the tobacco processing industry. It fulfills the demands of the tobacco industry (engineering database). The material is free of undesirable and prohibited ingredients, as required by well-known manufacturers of tobacco products.

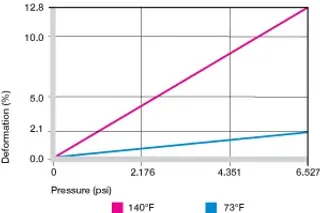

Deformation under load and temperatures

Compressive Strength

iglide® T220 plastic bushings can be stressed up to the permitted limit of 6,527 psi. However, the level of the load has an influence on the bushing's wear. The permitted load is limited by higher temperatures.

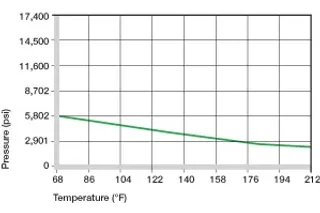

Maximum recommended surface pressure dependent on the temperature

Temperatures

The bushings made of iglide® T220 can be used continuously up to 212° F. Temperatures up to 320° F are permitted on the short term. The elasticity of the bushing is dependent on the temperature. Even 140° F leads to a clear increase in elasticity. A mechanical fastening should be considered from 140° F upward.

Please contact us if there is any query about the bushing and their application.

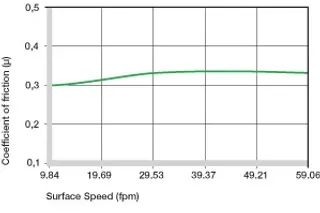

Coefficients of friction dependent on the surface speed, p = 108 psi

Friction and wear

As the requirements of the tobacco processing industry was strictly complied with in the development of the material, the application of friction-minimizing additives was limited. Hence the coefficients of friction and wear of the iglide® T220 plastic bushings are clearly behind those of the best iglide® bmaterials.

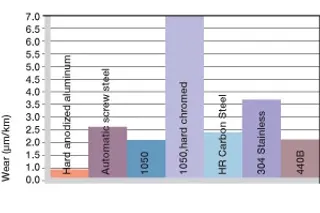

Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

The graph show the results of tests for the wear resistance with different shaft materials. By the observance of the recommendations, the service life of a bushing application can be distinctly improved. The graph shows that with increase in load, the bearing responds with stronger increase in wear. Therefore care should be taken to maintain the loads under 725 psi through adequate dimensioning of the bushing.

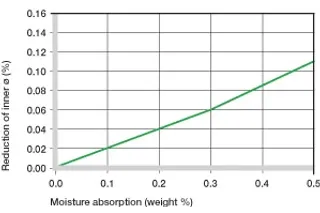

Influence of moisture absorption of iglide® T220 plastic bushings

Radioactive rays

iglide® T220 plastic bushings are radiation resistant up to a radioactive intensity of 3 x 10² Gy.