Change Language :

Plain bearing liner for drylin® linear systems

Choose the suitable liner for your drylin® linear system

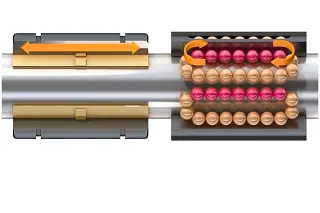

The principle: "sliding instead of rolling"

The advantages of plain bearing liners compared to recirculating ball bearings

The iglide® plain bearing liners made of high-performance polymer used for drylin® linear systems are completely self-lubricating and maintenance-free. The principle of the plain bearing leads to further advantages in favour of a drylin® linear system.

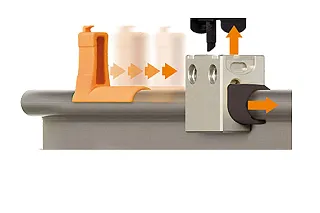

Replace plain bearing liner

Quick change – smart and time-saving

With the innovative WJ200UMA-01-AL pillow block from the drylin® W product range, it is possible to replace the plain bearing liner even more easily without complicated disassembly work being required. The tool supplied makes it possible to exchange the plain bearing liner within seconds. This saves valuable time and costs!

Linear technology by igus®

The versatility of plain bearings in all drylin® linear systems

- Maintenance-free solution

- Wear-resistant

- Resistant to impacts and vibrations

- Corrosion-resistant

- Resistant to dirt, dust and humidity

- Low coefficient of friction

- Weight-optimized

- 100% self-lubricating

Request a free drylin® W sample now!

With its extensive modular system, drylin® W profile guides offer greatest product diversity. See for yourself the benefits of our drylin® W profile guides with our sample box.

Looking to Speak with an Expert?

Whether you're interested in fully assembled solutions or looking to build your own customizable project, let us assist you with a solution based on your specific application and requirements. Contact Matt Mowry at (800) 521-2747 .