Change Language :

iglide® UW500 - Material data

Materials table

| General features | Unit | iglide® UW500 | Test method |

|---|---|---|---|

| Density | g/cm3 | 1.49 | |

| Color | Black | ||

| Max. humidity absorption at 73° F/50% R. H. | Wt.-% | 0,1 | DIN 53495 |

| Max. water absorption | Wt.-% | 0.5 | |

| Coefficient of friction, dynamic against steel | µ | 0.20 - 0.36 | |

| p x v value, max. (dry) | psi x fpm | 10,000 | |

| Mechanical properties | |||

| Modulus of elasticity | psi | 2,321.000 | DIN 53457 |

| Tensile strength at 68° C | psi | 37,710 | DIN 53452 |

| Compressive strength | psi | 20,310 | DIN 53452 |

| Maximum recommended surface pressure (68° F) | psi | 20,310 | |

| Shore D hardness | 86 | DIN 53505 | |

| Physical and thermal properties | |||

| Upper long-term application temperature | °F | 482 | |

| Upper short-term application temperature | °F | 572 | |

| Lower application temperature | °F | 599 | |

| Thermal conductivity | [W/m x K] | 0.60 | ASTM C 177 |

| Coefficient of thermal expansion (at 73° F) | [K-1 x 10-5 ] | 4 | DIN 53752 |

| Electrical properties | |||

| Specific volume resistance | Ωcm | < 109 | DIN IEC 93 |

| Surface resistance | Ω | < 109 | DIN 53482 |

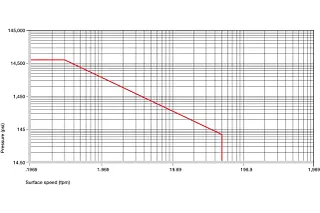

Permitted p x v values

For iglide® UW500 plastic bushings with 0.039 inches wall thickness in dry operation against a steel shaft, at 68° F, installed in a steel housing.

The plastic bushings made of iglide® UW500 have been developed for underwater applications with higher temperatures. Examples for this are water pumps in automotive construction, and also medical technology and related areas. iglide® UW500 can be used in applications with continuous temperatures of 302° F. With special fastening of the bushing, these temperatures can go even beyond 392° F.

The specifications in this section characterize iglide® UW500 in dry operation, if the underwater application is not expressly stated.

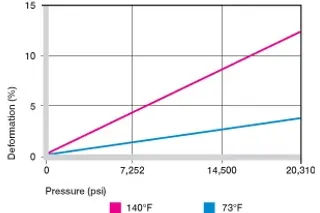

Deformation under load and temperatures

Compressive Strength

The graph shows how the iglide® UW500 plastic bushing elastically deform under loads. On the previous page, the graph shows the maximum p x v values at room temperature. The high p x v values are attained through the high temperature resistance.

Permitted surface speeds

iglide® UW500 is excellent in both dry and wet operations. Through a hydrodynamic lubrication, attained under water with high speeds, surface speeds far above 394 fpm can be achieved. In dry operation the iglide® UW500 plastic bushings can be used anyhow up to 295 fpm on the short term.

| fpm | Rotating | Oscillating | Linear |

|---|---|---|---|

| Constant | 158 | 118 | 394 |

| Short-term | 295 | 217 | 591 |

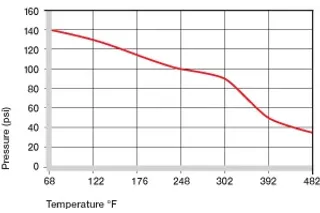

Maximum recommended surface pressure dependent on the temperature

Temperatures

The iglide® UW500 takes the top position also with regard to temperature resistance. With a permitted long-term application temperature of 482° F, the iglide® UW500 tolerates even 599° F on a short term. The bushings fastened by press-fit can indeed creep out through relaxation at temperatures above 302° F. Therefore for temperatures above 302° F, the firm seating of the bushing in the housing should be ascertained in tests, or, if necessary, ensure the firm fastening of the bushing through suitable mechanical measures.

Please contact us if there is any query about the application of the bushing.

Temperature limits

| iglide® UW500 | Application temperature |

|---|---|

| Lower | - 148 °F |

| Upper, long-term | + 482 °F |

| Upper, short-term | + 572 °F |

| Additional axial securing | + 302 °F |

Coefficients of friction dependent on the surface speed, p = 108 psi

Friction and wear

With increasing load the friction of the bushing system with iglide® UW500 plastic bushing declines. Instead of that the coefficient of friction rises with increasing speed. This illustrates the excellent suitability of iglide® UW500 plastic bushing with high loads. Friction and wear also depend to a high degree on the reverse partner. Extremely smooth and extremely coarse shafts enhance the coefficient of friction of the bushing. Ideal are smoothed surfaces with an average surface finish of Ra of 0.6 to 0.8.

Please contact us for the specifications of shaft surface finishes in underwater applications.

Coefficients of friction for iglide® UW500 against steel (Shaft finish = 40rms, 50 HRC)

| iglide® UW500 | Dry | Grease | Oil | Water |

|---|---|---|---|---|

| Coefficients of friction µ | 0.1 - 0.4 | 0.09 | 0.04 | 0.04 |

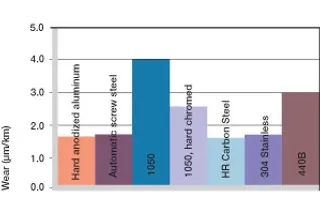

Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

The figures display a summary of the results of tests with different shaft materials conducted with plastic bushings made of iglide® UW500. With low loads in the rotating application, the coefficients of wear are ideal with 1050 hard chromed shafts.

Please contact us in case the shaft material scheduled by you is not included in this list.

Installation tolerances

iglide® UW500 plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9).

After the installation in a housing bore with H7 tolerance, the inner diameter of the bushingg automatically adjusts to F10 tolerance.

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® UW500 F10 [mm] |

|---|---|---|

| Up to 0.5 | 0 - 0,025 | +0,006 + 0,046 |

| > 3 to 6 | 0 - 0,030 | +0,010 + 0,058 |

| > 6 to 10 | 0 - 0,036 | +0,013 + 0,071 |

| > 10 to 18 | 0 - 0,043 | +0,016 + 0,086 |

| > 18 to 30 | 0 - 0,052 | +0,020 + 0,104 |

| > 30 to 50 | 0 - 0,062 | +0,030 + 0,150 |

Chemical resistance

iglide® UW500 plastic bushings have almost universal chemical resistance. They are affected only by concentrated nitric acid and sulfuric acid. The chemicals list given at the end of this catalog gives detailed information over this.

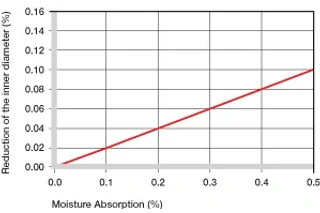

The humidity absorption of iglide® UW500 plastic bushings is extremely low. In standard climatic conditions, it lies below 0.1 Wt-%. Thus the iglide® UW500 plastic bushings can be even mounted for underwater applications without any adaptation to the installation conditions. The maximum water absorption is 0.5 Wt-%.

Radioactive rays

iglide® UW500 plastic bushings are radiation resistant up to a radioactive intensity of 1 x 105 Gy. iglide® UW500 thus figures among the most radiation-resistant materials in the iglide® product range. iglide® UW500 is extremely resistant to strong gamma rays and withstands a radiation dose of 1,000 Mrad without any perceptible loss of any of its properties. The material also overcomes an alpha or beta radiation of 10,000 Mrad virtually unscathed.

UV-resistant

The excellent material features of the iglide® UW500 do not alter under UV radiation and other climatic influences.

Vacuum

The iglide® UW500 plastic bushings can also be used almost unrestrictedly in vacuum. An evaporation takes place only to a minor degree.

| Medium | Resistance |

|---|---|

| Alcohol | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | + |

| Strong acids | + |

| Weak alkaline | + |

| Strong alkaline | + |

| + resistant 0 conditionally resistant - non-resistant |

Electrical properties

Plastic bushings made of iglide® UW500 are electrically conductive.

Delivery program

The iglide® UW500 plastic bushings are manufactured according to order specifications.

| Specific volume resistance | Surface resistance |

|---|---|

| > 109 Ωcm | > 109 Ω |