Change Language :

iglide® J 260 - material data

| General features | Unit | iglide® J260 | test method |

|---|---|---|---|

| Density | g/cm3 | 1,35 | |

| Color | yellow | ||

| Max. moisture absorption at 73°F/50% R. H. | Wt.-% | 0.2 | DIN 53495 |

| Max. moisture absorption | Wt.-% | 0.4 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.06 - 0.20 | |

| P x v value, max. (dry) | psi x fpm | 10,000 | |

| Mechanical properties | |||

| Modulus of elasticity | psi | 319,100 | DIN 53457 |

| Tensile strength at 68° F | psi | 8,702 | DIN 53452 |

| Compressive strength | psi | 7,252 | |

| Permissible static surface pressure (68° F) | psi | 5,802 | |

| Shore D hardness | 77 | DIN 53505 | |

| Physical and thermal properties | |||

| Upper long-term application temperature | °F | 248 | |

| Upper short-term application temperature | °F | 284 | |

| Lower application temperature | °F | -148 | |

| Thermal conductivity | [W/m x K] | 0.24 | ASTM C 177 |

| Coefficient of thermal expansion (at 73° F) | [K-1 x 10-5] | 13 | DIN 53752 |

| Electrical properties | |||

| Specific volume resistance | Ωcm | >1012 | DIN IEC 93 |

| Surface resistance | Ω | >1010 | DIN 53482 |

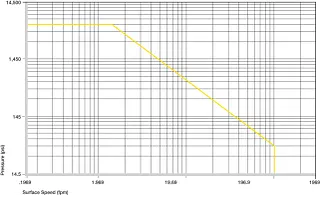

Permitted PV values

iglide® J260 is a perfect material for long service life and best coefficient of friction with special operating cinditions such as contact with plastic shafts.

Permitted PV values for iglide® J260 plastic bushings with 0.03937 in (1 mm ) wall thickness in dry operation against a steel shaft, at 68°F, installed in a steel housing.

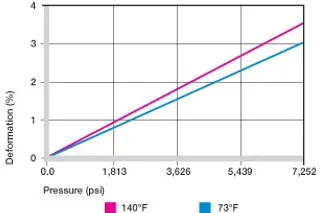

Deformation under load and temperature

Surface Pressure

The graph shows the elastic deformation of iglide® J260 during radial loading. At the recommended maximum surface pressure of 5,802 psi the deformation is less than 2.5%. The plastic deformation is minimal up to a pressure of approximately 14,500 psi. However, it is also dependent on the cycle life.

Permitted surface speeds

iglide® J260 is developed for low to medium surface speeds. The maximum values shown in the table can be attained only with minor pressure loads. At the specified speeds, an increase in temperature up to the long-term permitted value can occur due to friction. In practice these limit values are not always reached.

| fpm | Rotary | Oscillating | Linear |

|---|---|---|---|

| Constant | 197 | 137 | 591 |

| Short-term | 393 | 275 | 787 |

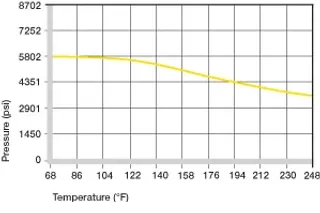

Recommended maximum permissible static surface pressure of iglide® J260 as a result of the temperature

Temperatures

iglide® J260 plastic bushings can be used between -148°F and +248°F. The short-term permitted maximum temperature is +284°F. The temperatures prevailing in the bushing system also have an influence on the bushing wear. The wear increases with rising temperatures, and the influence is especially marked from +176°F temperature onward.

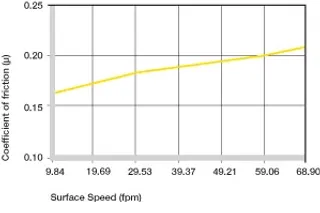

Coefficients of friction as a function of the running speed, p = 108 psi

Friction and wear

Just like the wear resistance, the coefficient of friction µ, friction coefficient in short, also alters with the load. Interestingly the coefficient of friction decreases with increasing load, whereas an increasing surface speed causes a slight rise in the coefficient of friction.

The friction and wear are also dependent, to a large degree, on the shaft material. Shaft that are too smooth increase both the coefficient of friction and the wear of the bushing. For iglide® J260 plastic bushing a ground surface with an average roughness of 32 rms is recommended.

| iglide® J260 | Dry | Grease | Oil | Water |

|---|---|---|---|---|

| Coefficients of friction μ | 0.06 - 0.20 | 0.09 | 0.04 | 0.04 |

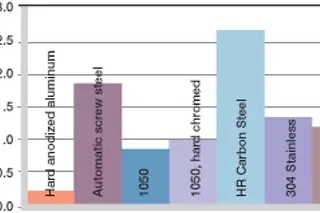

Wear, rotating application with different shaft materials, p = 145 psi, v = 59 fpm

Shaft Materials

The graphs show the results of testing different shaft materials with plastic bushings made of iglide® J260.

The graph on the left shows that iglide® J260 can be combined with various shaft materials. The hard anodized aluminum shaft perform the best at low loads, but iglide® J260 plastic bushings show good service life even on simple 1050 stainless steel and hard chromed shafts. In this connection it is important to know that with increasing loads the recommended hardness of the shaft increases. The soft shafts tend to wear more easily and therefore increase the wear of the overall system, if the loads exceed 290 psi.

The middle left graph shows that with increasing load the wear on hard-chromed shafts and 304 stainless rises less strongly than on 1050 and HR carbon steel shafts. The comparison of rotation and oscillating in the graph lower left makes it very clear where iglide® J260 plastic bushings are best used, especially in rotary operations.

Chemical Resistance

iglide® J260 plastic bushings are resistant to diluted alkalis, hydrocarbons and alcohols. The extremely low moisture absorption also allows them to be used in wet or damp environment.

The humidity absorption of iglide® 200 plastic bushings amounts to about 0,2% in standard climatic conditions. The saturation limit in water is 0,4 %. These values are so low that a consideration of the expansion due to moisture absorption can be neglected.

Radiation Resistance

Resistant up to a radiation intensity of 3x 102 Gy

UV-resistant

Partly resistant against UV rays

| Medium | Resistance |

|---|---|

| Alcohol | + to 0 |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | 0 to - |

| Fuels | - |

| Weak acids | - |

| Strong acids | - |

| Weak alkaline | + to 0 |

| Strong alkaline | + to 0 |

| + resistant, 0 conditionally resistant, - not resistant | |

| All specifications at room temperature [68°F] |

| Specific volume resistance | Surface resistance |

|---|---|

| > 1012Ωcm | > 1010Ω |

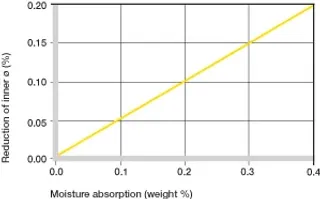

Effect of moisture absorption on iglide® J260 plastic bushings

Vacuum

In application in vacuum, the potentially existent moisture content is degassed. For this reason only the dry iglide® J260 plastic bushings are suitable for vacuum.

Electrical properties

Electrically insulating

Installation tolerances

iglide® J260 plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9). The bushings are designed for press-fit in a housing with h7 tolerance. After the installation in a housing with nominal diameter, the inner diameter of the bushing automatically adjusts to the E10 tolerance. Compared to the installation tolerance, the inner diameter varies according to moisture absorption.

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® J260 E10 [mm] | Housing H7 [mm] |

|---|---|---|---|

| Up to 3 | 0 - 0,025 | +0,014 +0,054 | 0 +0,010 |

| > 3 to 6 | 0 - 0,030 | +0,020 +0,068 | 0 +0,012 |

| > 6 to 10 | 0 - 0,036 | +0,025 +0,083 | 0 +0,015 |

| > 10 to 18 | 0 - 0,043 | +0,032 +0,102 | 0 +0,018 |

| > 18 to 30 | 0 - 0,052 | +0,040 +0,124 | 0 +0,021 |

| > 30 to 50 | 0 - 0,062 | +0,050 +0,150 | 0 +0,025 |

| > 50 to 80 | 0 - 0,074 | +0,060 +0,180 | 0 +0,030 |

| > 80 to 120 | 0 - 0,087 | +0,072 +0,212 | 0 +0,035 |

| > 120 to 180 | 0 - 0,100 | +0,085 +0,245 | 0 +0,040 |

| Table 07: Important tolerances for iglide® J260 bearings according to ISO 3547-1 after the press-in. |