Change Language :

iglide® H370 - Material data

| General features | Unit | iglide® H370 | Test method |

|---|---|---|---|

| Density | g/cm³ | 1.66 | |

| Color | Gray | ||

| Max. moisture absorption at 73° F/50% R. H. | Wt.-% | < 0.1 | DIN 53495 |

| Max. moisture absorption | Wt.-% | < 0.1 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.07 - 0.17 | |

| p x v value, max. (dry) | psi x fpm | 21,100 |

| Mechanical properties | Unit | iglide® H370 | Test method |

|---|---|---|---|

| Modulus of elasticity | psi | 1,610,000 | DIN 53457 |

| Tensile strength at 68° F | psi | 19,580 | DIN 53452 |

| Compressive strength | psi | 11,460 | |

| Permissible static surface pressure (68° F) | psi | 10,880 | DIN 53505 |

| Shore D hardness | 82 |

| Physical and thermal properties | Unit | iglide® H370 | Test method |

|---|---|---|---|

| Max. long-term application temperature | °F | 392 | |

| Max. short-term application temperature | °F | 464 | |

| Min. application temperature | °F | -40 | |

| Thermal conductivity | W/m x K | 0,5 | ASTM C 177 |

| Coefficient of thermal expansion | K^(-1) x 10^(-5) | 5 | DIN 53752 |

| Electrical properties | Unit | iglide® H370 | Test method |

|---|---|---|---|

| Specific volume resistance | Ωcm | < 10^5 | DIN IEC 93 |

| Surface resistance | Ω | < 10^5 | DIN 53482 |

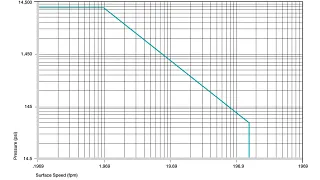

Permitted p x v values

For iglide® H370 plastic bushings in dry operation against a steel shaft, at 68° F.

iglide® H370 is an advanced development of the iglide® H series. The material is characterized by particularly low water absorption and clearly enhanced wear resistance. With regard to the mechanical and thermal characteristic values, iglide® H370 shows the same features as iglide® H.

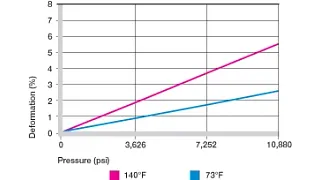

Figure 14.2: Deformation under load and temperatures

Compressive Strength

Figure 14.2 shows how iglide® H370 elastically deforms under radial load. Under the maximum recommended surface pressure of 10875 psi, the deformation at room temperature amounts to about 2.5%.

Maximum surface speed

Permitted surface speeds

The maximum permitted surface speed is dependent on whether the temperature in the bushing location rises strongly or not. iglide® H370 is suitable for surface speeds up to 236 fpm (rotating) and 787 fpm (linear) respectively.

| fpm | Rotating | Oscillating | Linear |

|---|---|---|---|

| Constant | 236 | 157 | 787 |

| Short-term | 295 | 216 | 984 |

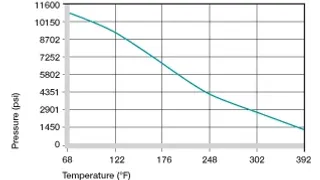

Figure 14.3: Maximum recommended surface pressure dependent on the temperature

Temperatures

iglide® H370 is an extremely temperature-resistant material. With a short-term permitted maximum temperature of 464° F, the iglide® H370 plastic bushings can in otherwise unloaded condition be subjected for instance, to a paint drying process. With increasing temperatures, the compressive strength of iglide® H370 plastic bushings decreases. Fig. 14.3 clarifies this connection.

The temperatures prevailing in the bushing system also have an influence on the bushing wear. The wear rises with increasing temperatures.

iglide® H370 loses about 75% of its compressive strength with a rise in temperature range, from room temperature to 302° F. In contrast the increase in wear is hardly noticeable in the same temperature range.

Temperature limits

| iglide® H370 | Application temperature |

|---|---|

| Lower | - 40 °F |

| Upper, long-term | + 392 °F |

| Upper, short-term | + 464 °F |

| Additional axial securing | + 212 °F |

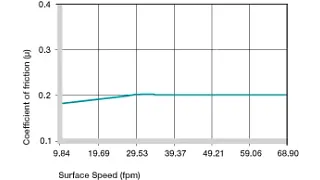

Figure 2.4: Coefficients of friction dependent on the surface speed, p =108 psi

Friction and wear

The coefficients of friction and wear in iglide® H370 are more favorable than in iglide® H. There is no better material than iglide® H370 especially for underwater applications. The coefficient of friction alters only little, like the wear resistance with increasing load and surface speed. This connection illustrates the excellent suitability of iglide® H370 plastic bushings with high loads.

Friction and wear also depend to a high degree on the reverse partner. Very smooth shafts increase the coefficient of both friction and wear. The ideally suited is a ground surface with an average roughness range of 8 - 16 rms.

Coefficients of friction for iglide® H370 against steel

(Shaft finish = 40 rms, 50 HRC)

Dry: 0.07 µ - 0.17 µ

Grease: 0.09 µ

Oil: 0.04 µ

Water: 0.04 µ

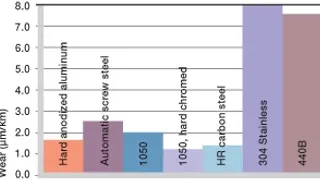

Fig. 2.7: Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

The diagrams display a summary of the results of tests with different shaft materials conducted with bushings made of iglide® H370.

For loads up to 290 psi, the hard-chromed shaft is the best counter partner for the iglide® H370 plastic bushings in rotating applications. The high wear values for 303 Stainless shafts, which have a tendency to stick-slip because of their very smooth surfaces. The HR Carbon Steel shaft has better rotational values than Cold Rolled Steel starting at 290 psi.

On the other hand, for oscillating movements, the 303 Stainless Steel shaft has a clear superiority. As the diagram shows, it generates, at 290 psi, a lower wear by the factor of 11 than the Cold Rolled Steel shaft.

Please contact us in case the shaft material scheduled by you is not included in this list.

Important tolerances for iglide® H370 plastic bushings according to ISO 3547-1 after the press-fit.

Installation tolerances

iglide® H370 plastic bushings are standard bushings for shafts with h-tolerance (recommended minimum h9).

After the installation in a housing bore with H7 tolerance, the inner diameter of the bushing automatically adjusts to F10 tolerance.

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® H [mm] |

|---|---|---|

| Up to 0.019685 | 0 - 0.0009842 | +0.0002362 + 0.0018110 |

| > 0.118 to 0.236 | 0 - 0.0011811 | +0.0003937 + 0.0022835 |

| > 0.236 to 0.394 | 0 - 0.0014173 | +0.0005118 + 0.0027953 |

| > 0.394 to 0.709 | 0 - 0.0016929 | +0.0006299 + 0.0033858 |

| > 0.709 to 1.181 | 0 - 0.0020472 | +0.0007874 + 0.0040945 |

| > 1.181 to 1.969 | 0 - 0.0024409 | +0.0009843 + 0.0049213 |

| > 1.969 to 3.150 | 0 - 0.0029134 | +0.0011811 + 0.0059055 |

Chemical resistance

iglide® H370 plastic bushings have a good resistance against chemicals. They are resistant to most lubricants. The iglide® is not affected by most weak organic and inorganic acids.

The moisture absorption of iglide® H370 plastic bushings is about 0.1% in standard climatic conditions. The saturation limit in water is likewise below 0.1%. iglide® H370 is therefore the best suited bushing material for underwater applications.

+ resistant

0 conditionally resistant

- non-resistant

| Medium | Resistance |

|---|---|

| Alcohol | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | + to 0 |

| Strong acids | + to - |

| Weak alkaline | + |

| Strong alkaline | + |

Radioactive rays

H370 withstands both the neutron and gamma particle radiations without noticeable loss to its excellent mechanical properties. iglide® H370 plastic bushings are radiation resistant up to a radioactive intensity of 2 x 10² Gy.

UV-resistant

iglide® H370 plastic bushings are permanently resistant against UV rays.

Vacuum

Water elements are degassed in the vacuum. Due to the low water absorption, an application in the vacuum is however possible.

Electrical properties

iglide® H370 plastic bushings are electrically conductive.

| Specific volume resistance | < 10^5 Ωcm |

| Surface resistance | < 10^5 Ω |

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert