Change Language :

iglide® Q - Material data

| General features | Unit | iglide® Q | Test method |

|---|---|---|---|

| Density | g/cm3 | 1.40 | |

| Color | Black | ||

| Max. moisture absorption at 73° F/50% R. H. | Wt.-% | 0.9 | DIN 53495 |

| Max. water absorption | Wt.-% | 4.9 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.05 - 0.15 | |

| p x v value, max. (dry) | psi x fpm | 16,000 | |

| Mechanical properties | |||

| Modulus of elasticity | psi | 652,700 | DIN 53457 |

| Tensile strength at 68° F | psi | 17,400 | DIN 53452 |

| Compressive strenght | psi | 12,910 | |

| Permissible static surface pressure (68° F) | psi | 14,500 | |

| Shore D hardness | 83 | DIN 53505 | |

| Physical and thermal properties | |||

| Max. long-term application temperature | °F | 275 | |

| Max. short-term application temperature | °F | 311 | |

| Min. application temperature | °F | -40 | |

| Thermal conductivity | [W/m x K] | 0.23 | ASTM C 177 |

| Coefficient of thermal expansion (at 73° F) | [K-1 x 10-5 ] | 5 | DIN 53752 |

| Electrical properties | |||

| Specific volume resistance | Ωcm | > 1015 | DIN IEC 93 |

| Surface resistance | Ω | > 1012 | DIN 53482 |

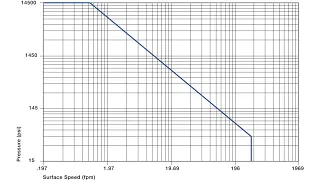

Permitted p x v values

For iglide® Q plastic bushings with 0.039 inches wall thickness in dry operation against a steel shaft, at 68° F, installed in a steel housing.

iglide® Q plastic bushings were developed especially for extreme loads. Under high loads, iglide® Q figures among the iglide® materials that by far display the best wear resistance. From a radial load of 3625 psi, it outclasses even bushings made of the highly wear-resistant iglide® L280. Specific solid lubricants, integrated in the material in an extremely fine way, take care that the maintenance-free dry operation is guaranteed under any load.

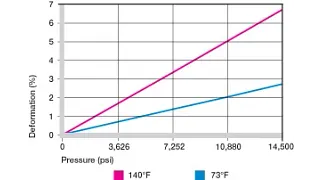

Deformation under load and temperatures

Compressive Strength

iglide® Q is a material used when high loads over 7250 psi are required. The graph shows the elastic deformation of iglide® Q with radial loads. Under the maximum recommended surface pressure of 14,500 psi, the deformation at room temperature amounts to less than 3 %.

Permitted surface speeds

Under extreme radial loads, the iglide® Q plastic bushings can reach the maximum p x v values, which are possible in the dry operation with plastic bushings. Though the iglide® Q plastic bushings have the greatest advantages with high loads and low speeds, high surface speeds are also attainable due to this bushing's excellent coefficients of friction. The values stated in table show the speed at which the temperature rises to the maximum permitted value as a result of friction.

| fpm | Rotating | Oscillating | Linear |

|---|---|---|---|

| Constant | 196 | 137 | 984 |

| Short-term | 393 | 275 | 1181 |

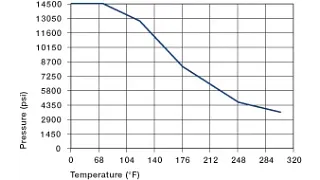

Maximum recommended surface pressure dependent on the temperature

Temperatures

The iglide® Q plastic bushings retain their excellent wear resistance in high temperatures as well. The upper long-term application temperature is 275° F. For a short-term, the material tolerates even 311° F. Due to various environmental influences, the press-fit of the bushings can also decline with low temperatures. For this reason, it may become necessary to fasten the bushing in the bore. Also note that the coefficient of friction strongly increases dependent on the temperature from about 212° F.

| iglide® Q | Application temperature |

|---|---|

| Lower | - 40 °F |

| Upper, long-term | + 275 °F |

| Upper, short-term | + 311 °F |

| Additional axial securing | + 122 °F |

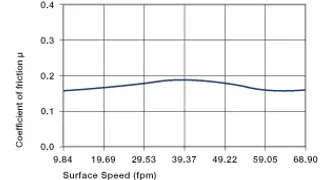

Coefficients of friction dependent on the surface speed, p = 108 psi constant

Friction and wear

Many dry-running plastic bushings feature decreasing coefficients of friction with increasing loads. iglide® Q surpasses the other iglide® bushings, which under high loads yet feature excellent coefficients of friction. Soon after the short run-in period, the coefficient of friction lowers to its final value. With these low coefficients of friction, iglide® Q is the right bushing material when the maximum wear resistance is required at extreme loads.

The counter partner too has significant influence on friction and wear. Extremely smooth shafts enhance the coefficient of friction of the bushing. For applications with high loads, we recommend hardened and ground surfaces with an average roughness range of 6 - 12 rms.

| iglide® Q | Dry | Grease | Oil | Water |

|---|---|---|---|---|

| Coefficients of friction µ | 0.05 - 0.15 | 0.09 | 0.04 | 0.04 |

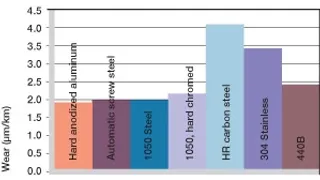

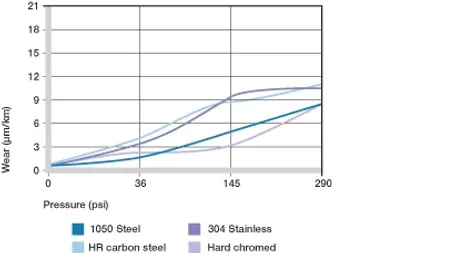

Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

The graphs show results of testing different shaft materials with plastic bushings made of iglide® Q.

iglide® Q plastic bushings have a higher average wear rate at low loads, than bushings made of iglide® J or iglide® L280. However, the strength of iglide® Q plastic bushings is its wear resistance at heavy loads and in oscillating operation. In oscillating movements, iglide® Q perform best against hard chromed or machined steel shafts.

Please contact us in case the shaft material scheduled by you is not included in this list.

iglide® Q plastic bushings are standard bushings for shafts with h tolerance (recommended minimum h9).

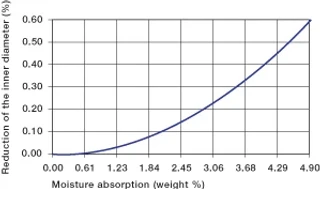

After the installation in a housing bore with H7 tolerance, the inner diameter of the bushing automatically adjusts to the E10 tolerance.

| Diameter d1 [inch] | Shaft h9 [inch] | iglide® Q E10 [inch] |

|---|---|---|

| Up to 0.019685 | 0 - 0.0009843 | +0.000551 + 0.0021260 |

| > 0.1181 to 0.2362 | 0 - 0.0011811 | +0.000787 + 0.0026771 |

| > 0.2362 to 0.3937 | 0 - 0.0014173 | +0.000984 + 0.0032677 |

| > 0.3937 to 0.7087 | 0 - 0.0016929 | +0.001260 + 0.0040157 |

| > 0.7087 to 1.1811 | 0 - 0.0020472 | +0.001575 + 0.0048819 |

| > 1.1811 to 1.9685 | 0 - 0.0024409 | +0.001969 + 0.0059055 |

| > 1.9685 to 3.1496 | 0 - 0.0029134 | +0.002362 + 0.0070866 |

Chemical resistance

iglide® Q plastic bushings have a good resistance against chemicals. They possess an excellent resistance to organic solvents, fuels, oils and greases.

The material is only partially resistant to weak acids and alkalis. The moisture absorption of iglide® Q plastic bushings amounts to about 0,9% in standard climatic conditions. The saturation limit in water is 4,9%. This should be considered according to application conditions.

Radioactive rays

iglide® Q plastic bushings are radiation resistant up to a radioactive intensity of 3 x 10² Gy.

UV-resistant

The tribological properties of the iglide® Q plastic bushings remain largely constant under climatic influences. However a minor embrittlement occurs in the material.

Vacuum

In application in vacuum, the potentially existent moisture content is degassed. For this reason only the dry iglide® Q plastic bushings are suitable for vacuum.

| Medium | Resistance |

|---|---|

| Alcohol | + to 0 |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | 0 to - |

| Strong acids | - |

| Weak alkaline | + |

| Strong alkaline | 0 |

| + resistant 0 conditionally resistant - non-resistant |

Electrical properties

Plastic bushings made of iglide® Q are electrically insulating.

| Specific volume resistance | Surface resistance |

|---|---|

| > 1015 Ωcm | > 1012 Ω |

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert