Change Language :

i.Sense EC.W Condition Monitoring Solution

Low cost service life sensor enables cost-effective real-time condition monitoring

Lifelong condition monitoring

The i.Sense EC.W sensor makes more system availability even more cost-effective than before. Due to the direct connection of the PLC machine control via potential-free contacts, real-time status monitoring for your gliding energy supply systems is possible.

For this purpose, the service life sensor is installed on one of the last crossbars on the fixed end and records the current condition of the chain with sensor technology from the in-house igus 3D printing; either directly for the PLC system control or via optional i.Cee module for comprehensive monitoring systems. This means that i.Sense EC.W makes it easier to avoid downtime and increase system availability.

Tech up

Cost down

Proof

Sustainability

EC.WLC color-coded status indicator

As an additional low-cost condition monitoring solution, igus® has also developed the EC.WLC status indicator. Unlike the EC.W, which integrates with an i.Cee module or PLC control system, the EC.WLC communicates the wear levels of an e-chain through a simple color-coded system.

The color of the indicator changes over time to reflect its condition. After intensive use, the red layer becomes visible. It indicates that there is a need for action. This way, the e-chain that the indicator is attached to can be evaluated and replaced if needed before failure could occur.

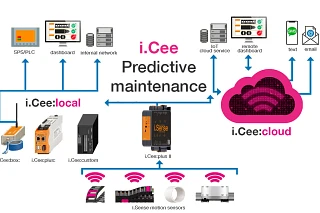

Integration into your network environment

Since the new EC.W sensor is part of the smart plastics i.Sense condition monitoring system, all of its data can also be evaluated in the i.Cee control cabinet module. This data can then be used to digitally control the system's alarm and escalation management.

The i.Cee module can be integrated into predictive maintenance concepts in a number of ways, from preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which immediately reports any unforeseen change via various mobile channels. All information is accessible in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert